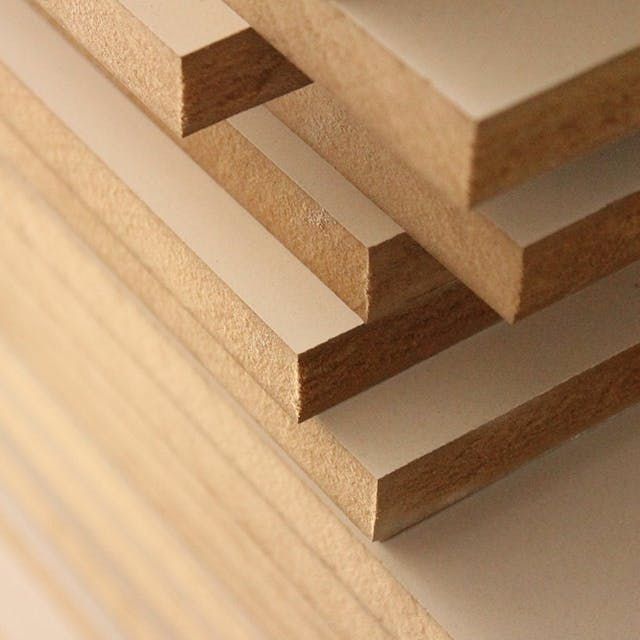

What we know as Medium-Density Fibreboard (MDF) today originally started as a composition of wood chips. Since then, the modern method involves breaking these chips down and using a defibrator to produce wood fibres. Then, in combination with resins and wax, it is heated and pressed to form flat, flush, and smooth panels – durable enough for an impressive range of purposes such as cabinetry, DIY, and furniture.

So Just What is MDF?

While the composition of MDF includes an ample amount of real wood, the wood in question has been fiberised and melded with water, wax, and resin. MDF boards involve wood chips, which otherwise wouldn’t have been useable like proper cuts of wood. This means an affordable product that is easy to work with, possessing most of the traits of real wood. There are a few key differences, however:

How Strong Is It?

Firstly, the eclectic blend of ingredients means that MDF didn’t form as a natural solid like wood does. Wood comes out as the stronger of the two, making it more suited for heavy loads, as well as woodworking activities. While both are workable with tools and can make excellent pieces of furniture, real wood’s natural composition makes it vastly superior for carving, sculptures, and creating intricate designs. Cutting MDF is prone to sawdust generation, and without a proper finish, it is vulnerable to swelling due to moisture ingress.

What About Looks?

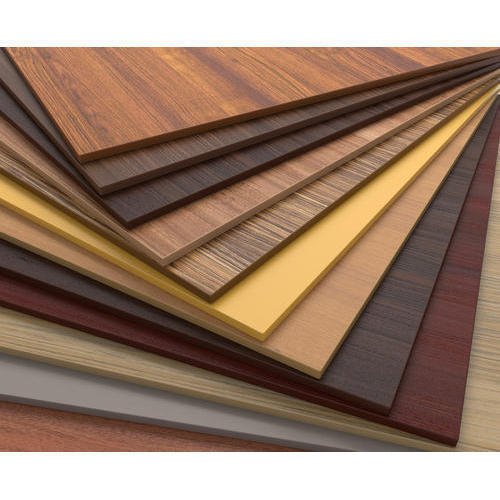

Secondly, the aesthetic appeal of real wood is something undeniable. A staple of modern and traditional designs, the textures and patterns play a crucial role in making homes and furniture feel genuine. Variants like pine, oak, or acacia provide nuanced depth and richness for a variety of settings. MDF, however, boasts an even greater degree of variety. Able to come in subtle melamine, glossy vinyl, or a deceptively realistic wood veneer, MDF offers unmatched versatility in customisation.

And Cost?

Among both real wood and its wood product alternatives, MDF holds strong in its position as an affordable and reliable material. Its lightweight nature makes it more manoeuvrable than real wood. A proper finish and edge application can mimic real wood quite convincingly. The latter, however, ages better, and is regarded to have better repairability – making real wood quite appealing in the long run.

The modern MDF manufacturing process is able to deliver affordable, quality products with good durability. With a bit of finishing and sealing, it proposes a remarkably competitive solution for cabinetry and furniture – being light and customisable. While it may not come with the authenticity or character of real wood, it comes incredibly close for typical home purposes.